Decarbon Debrief: NETL Partners with U. S. Steel to Capture Greenhouse Gas

US Steel testing membrane technology to decarbonize steel production

🚨 The Lead

The top story of the week.

NETL and US Steel Corporation are planning to test advanced membrane technology to absorb carbon dioxide emissions from steelmaking processes at their Edgar Thomson Plant in Braddock, Pennsylvania.

This project is part of the U.S. DOE/NETL Point Source Carbon Capture Program, which attempts to minimize CO2 emissions and achieve climate change targets. Carbon capture has the potential to minimize CO2 emissions from blast furnaces, making it a priority for the steel and iron industries. The testing of the promising NETL-developed membrane at the Edgar Thomson Plant is an essential step toward commercial implementation.

“This is an opportunity to play a role in shaping the future of greenhouse gas reduction for the entire steel industry. Our collaboration with NETL marks a great step forward in U. S. Steel’s ambition to achieving net-zero by 2050,” said Scott D. Buckiso, senior vice president and chief manufacturing officer, North American Flat-Rolled Segment. “Meeting our net-zero goal will take innovation, and our Edgar Thomson plant in the Mon Valley will play a significant role in exploring this crucial technology.”

Membranes provide a simple CO2 separation process with minimal moving parts and no CO2 regeneration stage, thereby saving money and lowering capital and maintenance expenses. Membrane-based carbon capture separates CO2 from flue gas using permeable materials, resulting in high-purity CO2 with a low nitrogen proportion that may be securely stored in deep geologic formations or utilized as feedstock for fuels and chemicals.

The National Carbon Capture Center (NCCC) of the US Department of Energy has completed lab-scale experiments on a membrane for carbon capture at power plants. The expanded field test at the Edgar Thomson Plant will remove CO2 from flue gas. NETL is designing the test unit, and a polymer membrane casting machine has been installed. The project aims to create membrane technology for industrial locations that emit large amounts of greenhouse gases. The unit is set to be deployed at the Edgar Thomson Plant in early 2025, with a six-month field test. The DOE/NETL Point Source Carbon Capture Program provided the financing.

Todd’s Take:

Join us this Wednesday to discuss CO2 Regulatory & Technical Challenges. The webinar is a collaboration with the Environmental Defense Fund, Interstate O&G Compact Commission, and Society of Petroleum Engineers.

Industrial decarbonization will take time. Many consider steel decarbonization as the most challenging ‘hard-to-abate’ sector due to the cost of electrifying steel production and total costs of transition.

Yet here are six themes that are happening now, but must be accelerated:

Transition to Low-Carbon Energy Sources: The steel industry is energy-intensive and relies heavily on coal and other fossil fuels for its energy needs. Transitioning to low-carbon or renewable energy sources, such as electricity from renewable sources or hydrogen produced from clean methods, is crucial for reducing emissions.

Technological Advancements: Developing and adopting breakthrough technologies like hydrogen-based direct reduction, carbon capture and utilization (CCU), and carbon capture and storage (CCS) can significantly reduce emissions associated with steel production.

Regulations and Incentives: Government policies, regulations, and incentives can play a vital role in driving the industry toward net-zero emissions. This can include carbon pricing, tax incentives for low-carbon technologies, and setting emissions reduction targets.

Investment in R&D: Significant investment in research and development is necessary to advance technologies and processes that can make the steel industry more sustainable.

Collaboration: Collaboration among steel manufacturers, governments, project developers, and environmental organizations can help set clear goals, share best practices, and work collectively to achieve lower emissions.

Consumer and Market Demand: Increasing consumer demand for sustainably produced steel and market incentives for low-carbon products can drive industry efforts to reduce emissions.

Often, we want to see results now. With DOE providing the funding and US Steel providing the steel production test-bed, the entire sector will benefit.

✨ This Week in Decarbonization

Highlights from the week’s most popular stories in industrial decarbonization.

🛠️ Baker Hughes and Venture Global Announce Expanded Master Equipment Supply Agreement to Support

🏆 ADIPEC Awards 2023 finalists announced; eight new categories address key energy and climate challenges

🙌 CarbonClear and Innovex Partners to Issue Data-Driven Carbon Credits from Off-Grid Solar

🚘 Lydian Raises $12M for Energy-Efficient E-fuels

🛑 AFC Energy and TAMGO sign exclusive distribution agreement for Zero Emission H-Power Fuel Cell Generators to Saudi and MENA Markets

🏢 HIF Global, Porsche and Volkswagen Group Unveil New Direct Air Capture Unit

💡 FuelCell Energy and Toyota Announce Completion of World's First "Tri-gen" Production System

💧 Fidelis New Energy selects Battelle Carbon Services as its Subsurface Contractor for Carbon Capture and Sequestration in Support of the Mountaineer GigaSystem™ Hydrogen Project in West Virginia

✨ Zefiro Methane Corp. & X Machina Capital Strategies to Co-Host 2023 NYC Climate Week Event

🚢 Advent Technologies Unveils its Serene Power Systems, Providing Clean Electric Power to the Marine Industry

☁️ Capture This CO2

A single carbon capture or hydrogen project in industrial decarbonization.

Alberta Carbon Grid

🏭 Operator: Pembina Pipeline

📌 Location: Alberta

⛽ Industry: Carbon Storage

🦺 Project Status: Early Development

🌱 Project Type: Commercial

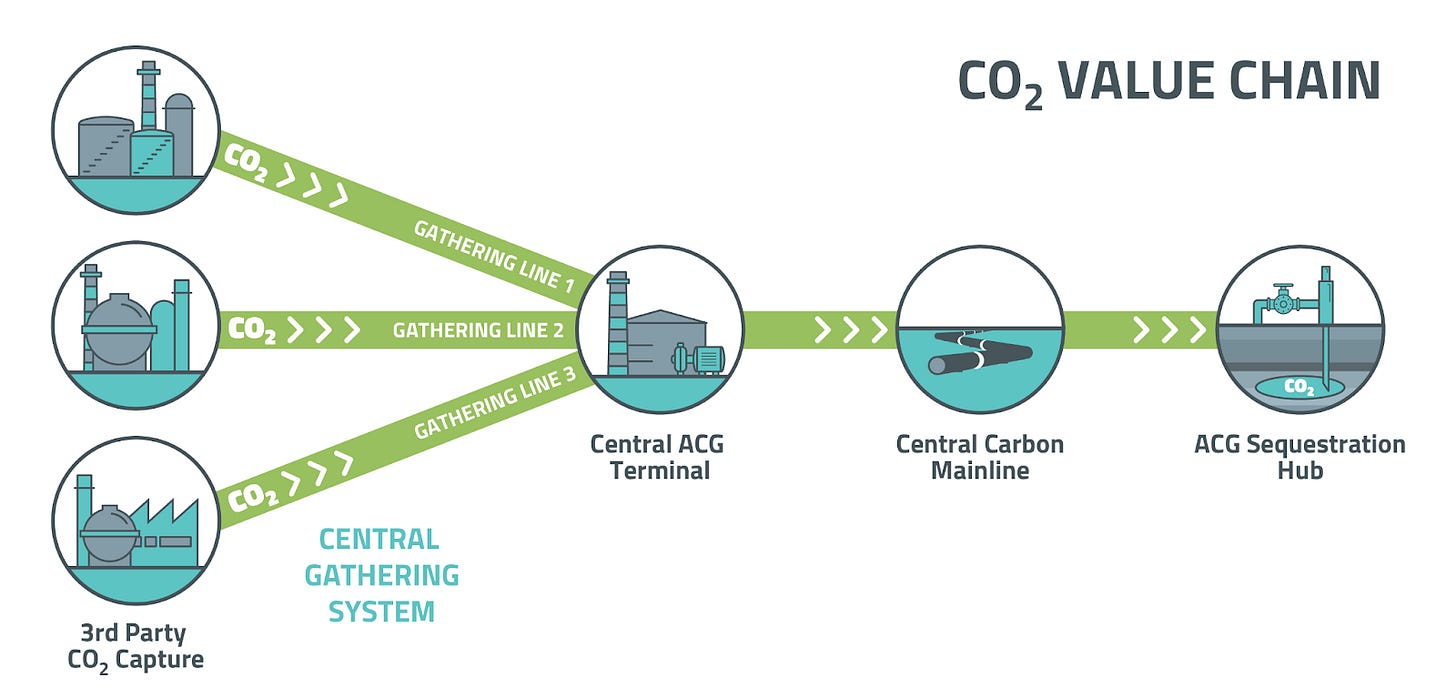

The Alberta Carbon Grid (ACG) is a world-class carbon transportation and sequestration solution designed to serve a wide range of clients, businesses, and sectors. ACG is a joint venture between Pembina and TC Energy that aims to provide CO2 transportation and sequestration solutions across Alberta by using our collective talents, experience, and broad network of existing rights-of-way.

They are looking into the possibility of establishing numerous ACG centers around the province that would be built to autonomously collect and store CO2 from clients in a variety of businesses in a safe and cost-effective manner. The long-term goal of the Alberta Carbon Grid is to transport and store up to 20 million tonnes of CO2 per year through many centers around the province.

ACG is working on the ACG Industrial Heartland project, a Carbon Capture, Utilization, and Storage (CCUS) system in Alberta's Industrial Heartland to store CO2 and satisfy emissions objectives. The project, which will be developed in phases, has the ability to transport and keep up to 10 million tonnes of CO2 each year. Last March 2022, the Alberta Government requested ACG to participate in the CCUS process to analyze one of the most excellent Areas of Interest for securely storing carbon from industrial emissions.

ACG has signed a carbon sequestration evaluation agreement with the Alberta government, acquiring the right to examine approximately 900,000 hectares of prime property north of Fort Saskatchewan, Alberta. The project is currently in its early phases and will give updates as more information becomes available.

ACG sequestration hub Area of Interest

🌍 Elsewhere

Highlights from research, data, or media partners covering the Energy Transition.

The UN's first official progress report indicates that the world is not on track to meet the long-term goals of the Paris Agreement, including limiting global warming to 1.5 degrees Celsius above mid-19th century levels, despite the successful implementation of the 2015 Paris Treaty in driving climate action.

Global greenhouse gas emissions must peak by 2025 and then fall significantly to meet the 1.5C target, according to the so-called stocktake, which is based on a major scientific review by the UN's IPCC science advisory group.

Achieving net zero carbon emissions by 2050, another Paris target, will need the phase-out of all fossil fuels whose emissions cannot be collected or paid for. The speed with which the global economy may get rid of oil, gas, and coal will be vigorously debated in December at the two-week COP28 negotiations in Dubai, which begin in late November and will be attended by over 200 countries.

"We need to triple renewable energy by 2030, commercialize other zero-carbon solutions like hydrogen, and scale up the energy system free of all unabated fossil fuels," said COP28 president Sultan al-Jaber, CEO of the UAE's state oil giant ADNOC.

The UN's first scorecard on the world's progress in meeting Paris Agreement climate goals emphasizes the need for a significant increase in clean power and the phase-out of unabated fossil fuels. The report highlights the need for just energy transitions to net zero emissions, which have already peaked in developed and developing countries.

That's it for this week. If you'd like to dive into the data a little more with me, hit reply.